Since then, the vacuum insulated glass, which provides ultra-thermal insulation, noise reduction, and condensation-free features, has become increasingly known to the public and found applications in the fields of communications, energy conservation, and emission reduction under the national “Carbon peak and carbon neutrality” strategy. Because there are so many different types of vacuum insulated glass products and technologies on the market today, vacuum insulating glass is here to help you go through them all and find the ones that are the most reliable.

The idea of vacuum insulated glass (VIG) and the structural design

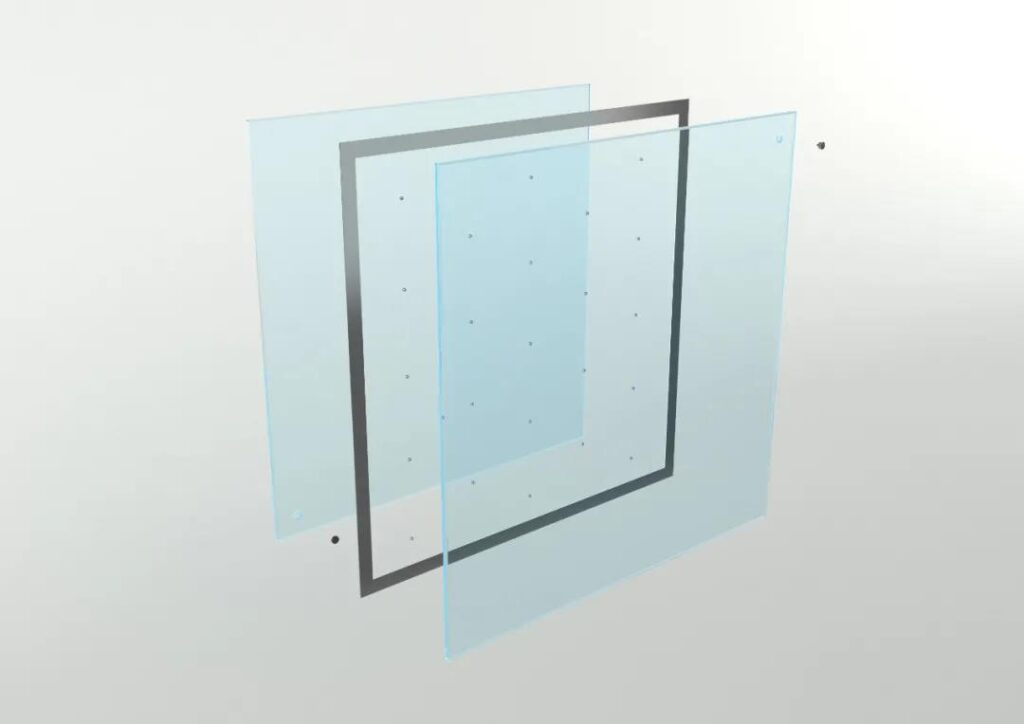

Two or more glass panes are separated by spacers in vacuum-insulated glass. After the edges have been sealed, the air between the two panes of glass is removed, leaving a vacuum. The next generation of energy-saving glass products, vacuum insulated glass, utilises vacuum space’s near-zero heat and sound transfer properties to provide remarkable performance in extreme thermal insulation and noise reduction of vacuum double glazing.

It’s time to get into the nitty gritty of vacuum-insulated glass

As far as thermal insulation and noise reduction are concerned, vacuum-insulated glass should be used. Vacuum insulated glass should also provide some protection as a secondary factor. In terms of design, it should, for example, keep the enery saving vacuum glass‘ characteristics. In order to be successful in the applications, vacuum insulated glass must also be able to tolerate external forces including wind loads and temperature loads. An further requirement for long term reliability is that the performance of vacuum insulated glass must be constant.

What type of testing does vacuum insulated glass have to undergo before it can be used?

Safety testing, ageing testing, and online quality testing are all used to guarantee that the glass is safe to use. The fragmentation test, impact test, and wind resistance test are just a few of the safety tests that are carried out. There are two forms of ageing testing: testing for weather resistance and testing for solar resistance. Air tightness tests and online performance tests are two of the many kinds of quality checks conducted.

For the manufacture of vacuum insulated glass, what type of certification is needed?

Product performance certification, safety certification, and qualification certification are all necessary for approved vacuum insulated glass. Among the most critical components of a certification is whether or not the product has been tested for its ability to keep out heat, sound, and wind. There are a number of safety certifications that are granted, including RoHS-compliant product certifications and safety glazing product certifications. That third-party certifying agency has evaluated and approved the vacuum insulated glass made by the manufacturer in terms of performance, quality, and suitability.

What are the benefits of vacuum insulated glass with metal sealing over normal glass?

Additionally, because the metal sealing material has a low melting point, the tempered glass will not be annealed during the edge sealing process. Because it is more pliable than plastic, metal is the better choice for this task. The metal sealing material is able to withstand more deformation while retaining an acceptable sealing effect due to the increased stresses placed on the vacuum glass by temperature fluctuations or other external forces. Vacuum insulated glass outperforms regular glass due to the benefits of metal sealing.